Home » Refrigerated Panels

Refrigerated Sandwich Panels

5124 reviews

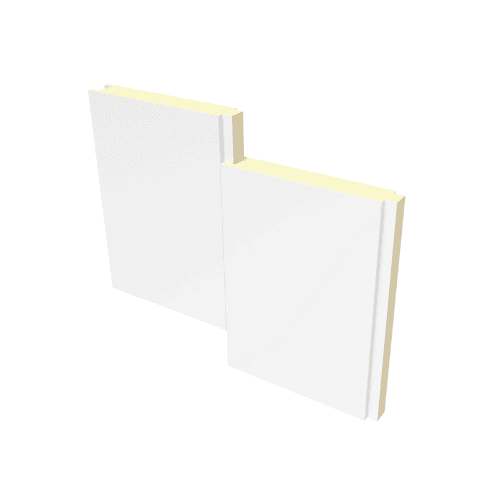

Insulated Metal Panels (IMPs) are premium high-performance building materials designed for exceptional thermal efficiency and structural strength. Our refrigerated sandwich panels for cold room are comprising outer steel skins that are securely laminated to a rigid polyisocyanurate foam core (PIR), these metal sandwich panels for cooler and freezer provide outstanding insulation for various applications. Walk-in coolers panels have a core thickness of at least 1.6 inches and a minimum foam density of 2.3 pounds per cubic foot (pcf), these industrial cold room panels not only ensure structural integrity but also deliver superior thermal performance. Custom cold room panels robust construction makes them ideal for use in commercial and industrial environments, providing reliable temperature control and energy efficiency while meeting the stringent requirements of modern building codes.

- High thermal insulation capacity (temperatures up to -4ºF)

- Available in various sizes and thickness. Made to measure, avoids waste

- Water vapour tight / High mechanical strength / High dimensional stability

- Resistant to aggresive environment

- White lacquered finish

- IN STOCK

Thermal isolation

Down to -4 ºF (-20 ºC)

Various sizes available

Made for fitting your requests

Quick assembly

And easy maintenance

High performance

Product quality assured

Applications of Refrigerated Panels

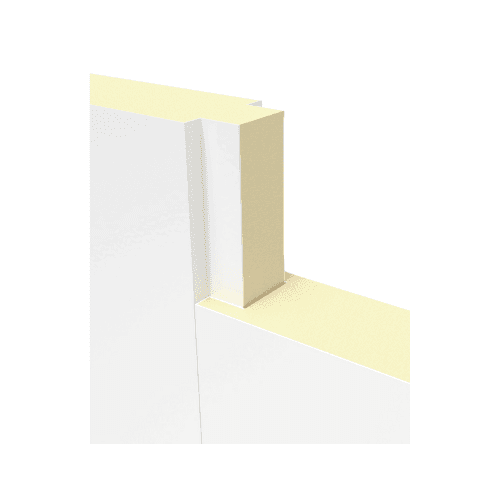

One of the standout features of our insulated metal panels is their innovative tongue-and-groove joining system, which creates tight and secure connections between refrigerated panels for cold storage. This design significantly reduces air leakage and ensures consistent insulation throughout the entire structure. By minimizing thermal bridges, this system enhances the overall energy efficiency of the building, making these panels ideal for environments where precise temperature control is critical for operational success.

Engineered specifically for a wide range of refrigeration projects and cold room warehouses, these refrigerated metal panels are indispensable in industries that require reliable cold storage and transportation solutions. They are particularly well-suited for the agro-food sector, where they are utilized in constructing facilities for the refrigerated transport, storage, and preservation of frozen and deep-frozen food products. Their exceptional ability to maintain stable temperatures is crucial for preserving the quality and safety of perishable goods, making them a vital component in the supply chain of the food industry.

In addition to the agro-food sector, these versatile panels can also be effectively used in other temperature-sensitive environments, such as pharmaceutical storage, chemical processing, and clean rooms, where maintaining a controlled environment is paramount for compliance and safety. Cold room panels outstanding durability, ease of installation, and excellent insulating properties make them a cost-effective solution for any project that demands efficient thermal regulation. Buy refrigerated panels for cold room

Available Sandwich Panel Sizes

Panel Thickness

- 1.5 in (40 mm)

- 2 in (50 mm)

- 2.5 in (60 mm)

- 3 in (80 mm)

- 4 in (100 mm)

- 5 in (120 mm)

- 6 in (150 mm)

Panel Width

- 39.5 in (1000 mm)

- 39.5 in (1000 mm)

- 39.5 in (1000 mm)

- 39.5 in (1000 mm)

- 39.5 in (1000 mm)

- 39.5 in (1000 mm)

- 39.5 in (1000 mm)

Panel Length

- Up to 139 ft (11,900 mm)

- Up to 139 ft (11,900 mm)

- Up to 139 ft (11,900 mm)

- Up to 139 ft (11,900 mm)

- Up to 139 ft (11,900 mm)

- Up to 139 ft (11,900 mm)

- Up to 139 ft (11,900 mm)

Panel Thickness

- 1.5 in (40 mm)

- 2 in (50 mm)

- 2.5 in (60 mm)

- 3 in (80 mm)

- 4 in (100 mm)

- 5 in (120 mm)

- 6 in (150 mm)

Panel Width

- 39.5 in (1000 mm)

Panel Length

- Up to 39 ft (11,900 mm)

Looking to buy refrigerated panels for your cold room? At Mike’s Panels, we offer an extensive range of high-performance refrigerated panels designed to meet all your cold storage needs. Our insulated panels are engineered with a robust polyisocyanurate foam core, ensuring exceptional thermal efficiency and structural integrity.

These refrigerated panels feature a tongue-and-groove joining system that provides tight, secure connections, minimizing air leakage and enhancing overall energy efficiency. Ideal for a variety of applications, including walk-in coolers, freezers, and specialized refrigerated storage facilities, our cold room panels are specifically designed to maintain precise temperature control essential for preserving perishable goods.

Whether you’re involved in the food industry, pharmaceuticals, or any sector requiring reliable cold storage solutions, our panels deliver superior performance and durability. Buy refrigerated panels from Mike’s Panels and experience the quality and reliability that set us apart as a leading supplier of refrigerated panels in the USA.

Technical Characteristics of Insulated Metal Panels

Layers:

- Exterior face:

- – Thicknesses of outer face: 0.020 in (0.5 mm), 0.024 in (0.6 mm), 0.028 in (0.7 mm)

- – Exterior face material: .G90 galvanized or AZ50 aluminum-zinc, coated steel in

- Exterior face:

- Interior face:

- – Thicknesses of inner face: GAUGE 26/24/22

- – Interior face material: .26 GA and above

- Coatings:

- – Polyester 25um (1 mil)

- – PVDF 25um / 35um (1 mil / 1.38 mils)

- – Granite HDX / SDP 50 (2,16 mils)

- Outer ribbing:

- – Standard / flat

- Inner ribbing:

- – Standard / flat

- Type of core:

- – Polyisocyanurate (PIR)

- Core density:

- – 40 Kg/m3 (2.3 PCF)

- Interior face:

Testing and approvals:

- Fire:

- – ASTM E 84 Results: Flame spread index 20 Smoke developed index 300

- Strength:

- – ASTM E 8 Results: > 32 ksi steel

- Fire:

Functions and benefits of our panels

- – Excellent aesthetics

- – High thermal insulation capacity

- – High mechanical strength

- – High dimensional stability

- – Water vapour tight

- – A versatile material that allows any configuration

- – Quick to install and easy to maintain

- – Easily removable

- – Made to measure, avoids waste

- – Resistant to aggresive environment

Layers:

- Exterior face:

- – Thicknesses of outer face: 0.020 in (0.5 mm), 0.024 in (0.6 mm), 0.028 in (0.7 mm)

- – Exterior face material: .G90 galvanized or AZ50 aluminum-zinc, coated steel in

- Interior face:

- – Thicknesses of inner face: GAUGE 26/24/22

- – Interior face material: .26 GA and above

- Coatings:

- – Polyester 25um (1 mil)

- – PVDF 25um / 35um (1 mil / 1.38 mils)

- – Granite HDX / SDP 50 (2,16 mils)

- Outer ribbing:

- – Standard / flat

- Inner ribbing:

- – Standard / flat

- Type of core:

- – Polyisocyanurate (PIR)

- Core density:

- – 40 Kg/m3 (2.3 PCF)

Testing and approvals:

- Fire:

- – ASTM E 84 Results: Flame spread index 20 Smoke developed index 300

- Strength:

- – ASTM E 8 Results: > 32 ksi steel

- – ASTM E 8 Results: > 32 ksi steel

Functions and benefits of our panels

- – Excellent aesthetics

- – High thermal insulation capacity

- – High mechanical strength

- – High dimensional stability

- – Water vapour tight

- – A versatile material that allows any configuration

- – Quick to install and easy to maintain

- – Easily removable

- – Made to measure, avoids waste

- – Resistant to aggresive environment

EXPERTS IN REFRIGERATED PANELS

Sandwich Panels

for Cold Rooms

Refrigerated sandwich panels are essential components for building high-performance cold rooms and freezer spaces. These insulated metal panels are designed with superior insulation properties, ensuring energy efficiency and maintaining optimal temperature control. Sandwich panels for cold room are typically composed of an insulated core, such as polyurethane or polyisocyanurate foam, sandwiched between two metal sheets, these metal sheet panels offer robust durability, making them ideal for both commercial and industrial cold storage applications.

At Mike´s Panels, our high performance panels for cold storage are engineered to meet the specific needs of industries ranging from food storage to pharmaceuticals, providing long-term reliability with a variety of thickness options and thermal resistance levels. Our sandwich panels also come with easy installation features and meet stringent international standards for hygiene and fire resistance, ensuring that your cold storage space remains efficient and secure.

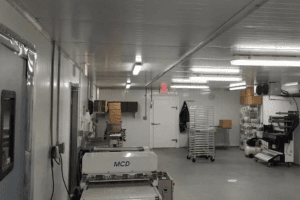

Our Cold Room Projects

At Mike’s Panels we are suppliers of cold room, we are dedicated to providing complete cold storage solutions that cater to every aspect of your refrigeration needs. From top-quality insulated panels and robust cold room doors to the construction of full walk-in freezers and coolers, our offerings cover every detail, including angular structures and refrigeration systems. We focus on delivering efficiency and durability in all our projects, making sure they meet the highest standards for sectors like food storage, pharmaceuticals, and industrial refrigeration. Our goal is to deliver turnkey solutions that ensure optimal performance and reliability. Buy refrigerated sandwich panels with us for top quality.

Related Products to Refrigerated Panel

Got Questions? We’ve Got Answers!

We understand that you may have questions before making a purchase, and we’re here to help! Our FAQ section covers the most common inquiries about our products, shipping, installation, and more. If you can’t find the information you’re looking for, feel free to reach out to our team directly. We’re always ready to assist you with any concerns you may have!

What are refrigerated sandwich panels made of?

Refrigerated sandwich panels consist of two outer metal sheets (usually galvanized steel or aluminum) with an insulating core in between, typically made of polyisocyanurate (PIR) foam. This core provides excellent thermal insulation, making the insulating panels ideal for maintaining controlled environments like cold rooms or freezers.

What are the benefits of using sandwich panels for cold rooms?

Sandwich panels for cold room offer superior insulation, which helps in maintaining low temperatures efficiently. Refrigerated panels are lightweight, easy to install, and provide excellent durability. Additionally, they are highly resistant to moisture, corrosion, and fire, making them an optimal solution for cold storage facilities.

Can refrigerated sandwich panels be customized in size and thickness?

Yes, refrigerated sandwich panels can be customized according to specific project requirements. They come in various thicknesses, ranging from 1.5in (40 mm) to 6 in (150 mm), depending on the insulation needs. Custom sandwich panel sizes can also be produced to fit any cold room or refrigeration unit.

How durable are refrigerated sandwich panels?

Refrigerated sandwich panels are designed for longevity. With proper installation and maintenance, they can last for several decades. The outer metal layers are typically coated for corrosion resistance, and the foam core is stable and maintains its insulating properties over time.

Are sandwich panels energy efficient?

Yes, cold room sandwich panels are highly energy-efficient due to their excellent thermal insulation properties. Cold storage panels help maintain a stable temperature within the cold room, reducing energy consumption for cooling systems and lowering operational costs in the long run.